Atlasfoam is a family of foam core materials, based on a unique and proprietary formulation designed by NMG Europe, with excellent toughness and resistance in relation to weight, outstanding resistance to static and dynamic loads and superior fatigue strength.

Concerning its chemistry, Atlasfoam is an interpenetrated polymer network (IPN) with a very high cross-linking degree, a molecular structure falling into the same category as cross-linked PVC foam, but using a thermoplastic based on polyester chemistry, allowing to combine high toughness and flexibility.

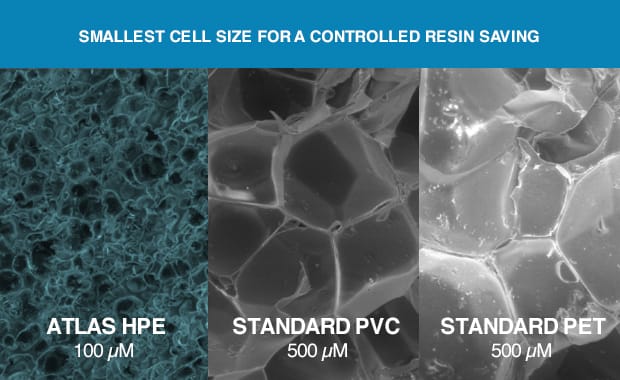

All Atlasfoam formulations present a closed, and very fine cellular structure. While all foams have a closed cellular structure, Atlasfoam presents the finest and most regular geometry so that smaller surface cavities at its surface minimise the resin needed to guarantee a perfect adhesion core to skin. Therefore Atlasfoam, requires less resin than other foams during composite manufacturing process, less than PVC foams and much less resin than PET foams. As a consequence, Atlasfoam allows for cost and weight saving while the quality of the sandwich composite is preserved.

BENEFIT

- Optimum peeling strength, high strength of core to skins bond

- Fatigue behaviour, a reliable choice in applications subjected to fatigue, slamming and impact loads

- Extreme damage tolerance, slowest microcracks growing rate

- Resin saving, lowest value of resin uptake and absorption among foams

- No change in manufacturing operations, compatibility with the most in-use types of resins and processes

- High heat distortion temperature

CERTIFICATION

The Atlasfoam series is DNV GL approved, according to DNV GL class programme DNVGL-CP-0084 – Type approval – Sandwich core materials.

More than 20.000 nacelles around the globe attests Atlasfoam’ quality.

ATLAS HPE

HIGH IMPACT AND FATIGUE RESISTANCE

Atlas HPE represents the result of an intensive R&D effort aimed at the improvement of core materials for structural applications. Thanks to an interpenetrated polymer network, IPN, using a thermoplastic based on polyester chemistry, Atlas HPE provides high resistance to dynamic loads in the long run. It also prevents from the risk of structural failure by its intrinsic capacity of energy adsorption and deformation.

Applications:

> wind blade

> naval & marine applications

> tidal turbine, wave energy and sea current exploitation technologies

> shipbuilding structural and semi-structural components

ATLAS HT

HIGH SERVICE TEMPERATURE

Atlas HT presents the same features of Atlas HPE with a plus with respect to service temperature behaviour and it is processable up to 150°C preserving its mechanical profile and dimensional stability. Atlas HT is the choice to overcome manufacturing issues such as high processing temperature, to bear exothermic reactions and to finally preserve laminate quality.

Thanks to Atlas HT it is possible to:

> Implement safely fast processing technologies

> Use fast reacting resin system

> Save manufacturing time

> Avoid waste of production

Applications:

> wind blade

> naval & marine applications

> tidal turbine, wave energy and sea current exploitation technologies

> shipbuilding structural and semi-structural components

ATLAS F

THE ENGINEERED FLEXIBLE FOAM

Atlas F is a rigid core material combining high toughness and flexibility.

It shows a high cross-linking degree, due to its thermosetting nature, and it has been engineered for applications requiring an optimum compromise between good mechanical properties, lightness, and low resin consumption.

Applications:

> all types of nacelle models

> yachts

> mobile homes and special vehicles

> light decorative panels

> lightweight furniture boards

Contact us for more information